Your cart is currently empty!

Make More, Spend Less:

The H2 Air Duct Cleaning Truck Mount is a recently developed system designed for high-

powered air duct cleaning. It has been completely redesigned to meet the demands of modern duct cleaning, and features the same ground-breaking technology as its predecessor, the H1. With enhanced efficiency and user-friendliness, this new system provides superior suction power and, crucially, is more profitable to operate.

New Mounting options:

The H2’s design allows the body to be upfitted on pretty much any 1-ton truck chassis or larger. The box is manufactured from aluminum, power coated (cannot rust), fashioned after the same design characteristics that firetrucks are modeled after. The H2 is available in both 12’- & 14’- foot body lengths. The H2 gives you plenty of storage space with a compact profile.

Less Weight, Less Fuel Bills:

The H2 is low weight, decreases the amount of fuel needed while greatly reducing the wear and tear on the truck chassis vital components, meaning you will not only save a ton of money on fuel you will also be reducing breakdowns from worn out transmission, engines brakes and shocks. The aluminum body also gets rid of all the issues of rust, and we also offer the body in either heavy duty paint or even powder coated for an extremely durable finish.

No more getting on the roof:

We have heard you loud and clear: duct cleaners don’t want to get on the roof just to start the duct cleaning vacuum. It can be tedious and dangerous especially in bad weather. We have designed a simple system to open and close the bag door on the roof in seconds, no motors to break, no tracks for ice to get caught in, watch the videos to see how easy it is. Ladder is still an option!

No More PTO (power take-off):

The biggest advantage to the new H series Duct Truck design is there is no more Power Take Off. The high-powered duct cleaning vacuum no longer is powered by the truck’s engine. Most people don’t realize it but the 300 HP engine under the hood only actually outputs around 42 HP to the fans drive shaft, so you’re wasting a lot of extra horsepower and burning a ton of extra fuel to power the fan when all you really needed was around 40 HP to power the fan and compressor, with the cost of fuel and repair bills this old method no longer makes any sense, not to mention drains your bank of any profit.

The H2 delivers more suction than our older style duct trucks while running a smaller dedicated engine to power the fan saving you loads of money in fuel savings while using far fewer moving parts to wear out. Most importantly, our new system is far better for the environment by greatly reducing greenhouse gas emissions.

There are several advantages to not using a PTO (power take-off) in certain applications, including:

- Greater flexibility: By not relying on a PTO, equipment can be operated independently of the vehicle’s engine, allowing for greater flexibility in how it is used. This can be particularly useful for equipment that needs to be used in different locations or situations where it is not practical to have the vehicle running constantly.

- Reduced maintenance: PTOs require regular maintenance and can be costly to repair if they fail. By not using a PTO, maintenance costs and downtime can be reduced.

- Improved fuel efficiency: Running a PTO can put a strain on the vehicle’s engine, leading to reduced fuel efficiency. By not using a PTO, fuel consumption can be optimized, resulting in cost savings over time.

- Quieter operation: PTOs can generate noise and vibration, which can be a concern in certain environments. By not using a PTO, noise levels can be reduced, making equipment operation quieter and potentially reducing noise pollution.

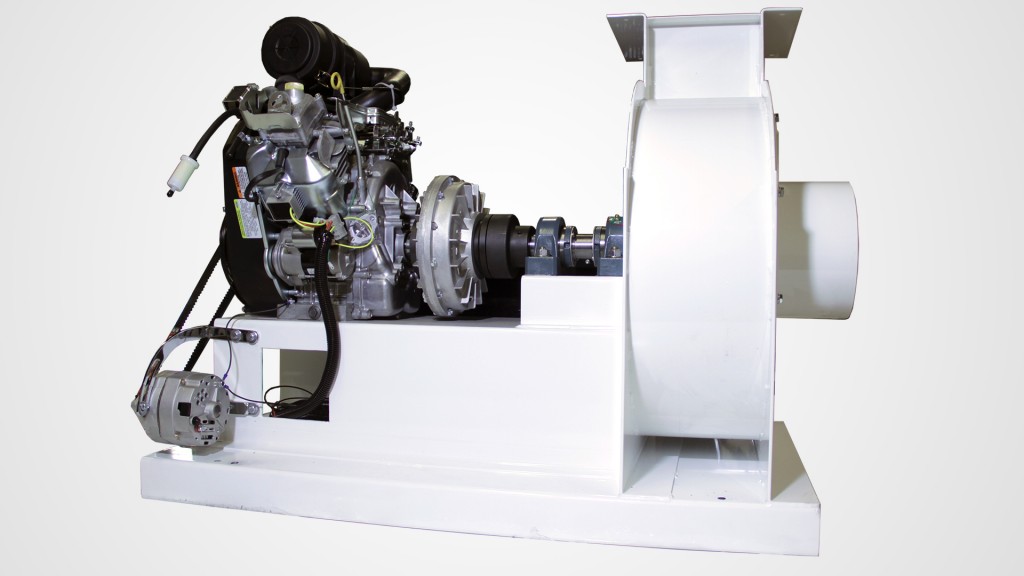

HAVAC System:

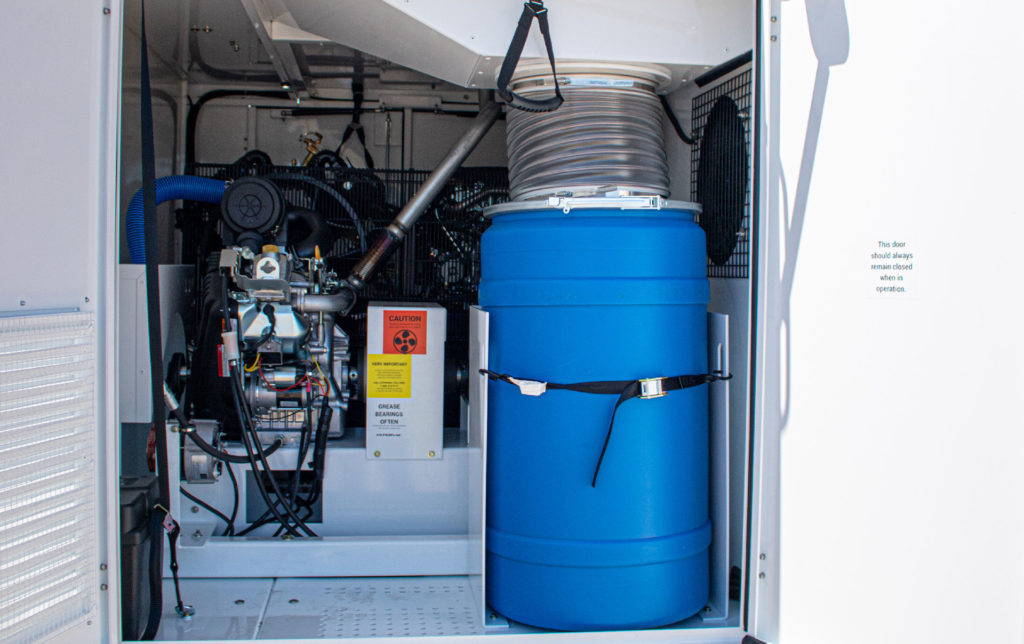

Our unique exclusively designed and built HAVAC vac system uses a 35 HP Briggs gas engine with fluid coupling and direct drive (no belts) to drive the fan. This is a simpler design as there are no belts to maintain on the fan and with less moving parts, breakdowns are less likely. The compressor is run separate with its own Gas engine, usually a Castair compressor with 43.6 CFM, 175 PSI. Suction competes with any other duct truck on the market.

Better Clean out system:

Debris clean out is no longer a tedious chore, why drive around with a 1000 pounds of your customers dirt in your truck which just adds weight, fuel, and repair costs. The new clean out bins consists of a simple lightweight drum which can be easily emptied on a weekly or monthly basis, plus for large jobs with hundreds of pounds of dirt removal then multiple bins can be brought in, no more making trips to the dump halfway through your work schedule.

We can design the truck your way, our new methods allow you to choose the way you hook up your hoses, run the vacuum intake from the back, or front sides.

Custom Design

We can design the truck your way , our new methods allow you to choose the way you hook up your hoses , run the vacuum intake from the back, or front sides.

Operations and Maintenance:

Learn the ins and outs of the H2 Duct Truck – from startup procedures to oil changes, this video will teach you how to operate your new H2 Duct Cleaning Truck.

You want your truck to not only last, but to also look good many years later too.