Your cart is currently empty!

Regenerative Tower Dryers

- Stronger Construction

- Aluminum billet and hard coat anodizing provides superior strength and corrosion resistance; eliminating casting porosity.

- 115V Control Time

- Timer cycles the towers into regeneration mode every 2 minutes.

- Customizable Performance

- Cartridge style regeneration orifices provide the ability to control the amount of air used to dry the towers. Reducing air volume and increasing orifice size can provide dew points down to -40F. Flow rates 100 CFM @ 175 psi. See orifice chart below.

- Dual 1″ Inlet / Outlet Ports

- Dual inlet ports and outlet ports provide easier installation and allow air to come in and out of the same side or in one side and out the other. This unique design allows for greater mounting flexibility.

- Less Parts, More Reliable

- Single piston spool per tower reduces the number of moving components; allowing for easier serviceability.

Regenerative Desiccant Air Dryers

| Part # Orifice Size | RDD50 Capacity | RDD100 Capacity |

| RD .015 | 0 – 10 CFM | N/A |

| RD .030 | 11 – 25 CFM | N/A |

| RD .045 | 26 – 40 CFM | 51 – 80 CFM |

| RD .060 | 41 – 50 CFM | 81 – 100 CFM |

| Part # RDD50 | 2 Tower Dryer | 0-50 CFM |

| Part # RDD!00 | 4 Tower Dryer | 51-100 CFM |

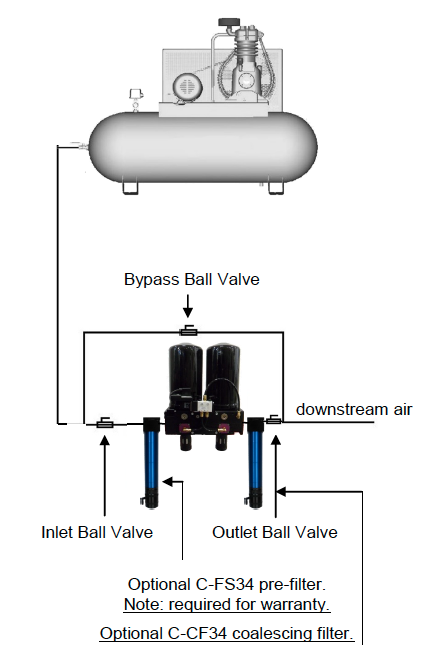

Optional: 3/4″ Dryer Mounting w/3-way Ball Valve (Part # DM75RD)

How Regenerative Dryers Work

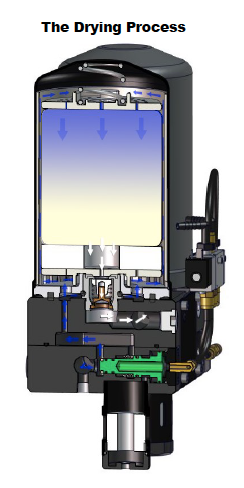

The Drying Process

- Pre filtered air enters the dryer and is channeled through the desiccant tower/s.

- Wet air passes through the tower/s where desiccant draws water vapor in while under pressure.

- After flowing through the desiccant, the now dry air is sent downstream.

- After two minutes, the control timer sends out a pilot signal shifting the internal piston. When the piston shifts, air is redirected from this tower/s to the opposite.

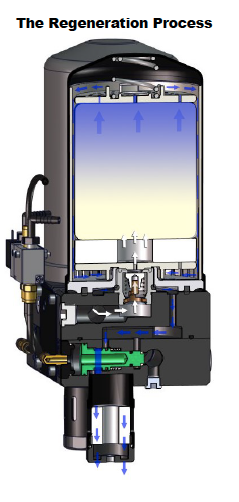

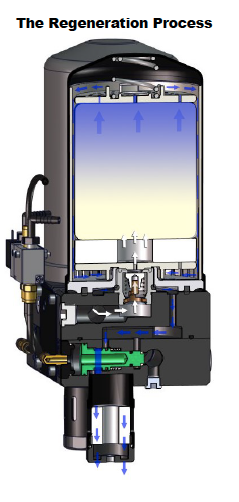

The Regeneration Process

- A small amount of air from the dry outlet on the opposite tower/s percolates up through the regeneration orifice and back through the desiccant filled tower/s.

- The desiccant is dried as the sweep air passes back through the media.

- With the use of this air, the tower/s discharge water vapor through the mufflers located below the dryer manifolds.

- After 2 minutes, the control timer sends out a pilot signal shifting the internal piston. When the piston shifts flow is reversed and this tower/s begins drying the air.

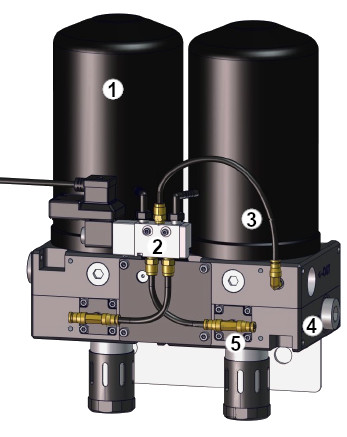

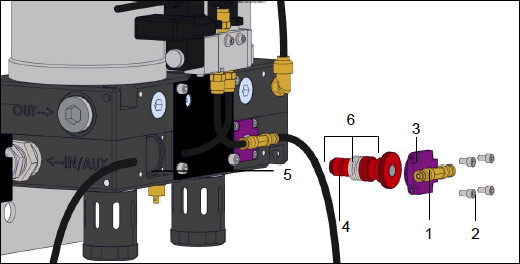

Service: Piston & Bore Lubrication

Depressurize the unit prior to any element change or service.

Each piston and bore (2) follows the same maintenance routine.

| 1 | Quick Connect Fitting |

| 2 | Socket Head Cap Screws |

| 3 | Piston Cover |

| 4 | Piston Spring |

| 5 | Piston Bore |

| 6 | Piston O-rings |

- Disconnect tubing from Quick-Connect Fitting located on the piston cover. Push in on brass ring. While holding ring in, pull out tubing.

- Remove the four Socket Head Cap Screws holding the piston cover in place (4mm Hex Key Wrench).

- Remove Piston Cover for access to piston.

- Using a finger or a ½-13 bolt, remove the Piston from the Piston Bore; be sure you remove the Piston Spring.

- Using the provided grease, lubricate the Piston Bore. Grease thoroughly.

- Lubricate the three Piston O-rings shown above. Grease thoroughly. Note: It is unnecessary to grease the bottom Piston O-ring.

- Re-install the Piston and Piston Spring.

- Reattach the Piston Cover using the four Piston Socket Head Screws. Torque to 75 in lb.

- Reconnect pilot line.

Regenerative Desiccant Air Dryers

| Part # RDD50 | 2 Tower Dryer | 0-50 CFM |

| Part # RDD100 | 4 Tower Dryer | 51-100 CFM |

Optional: 3/4″ Dryer Mounting w/3-way Ball Valve (Part # DM75RD)

Service Parts

| Description | Part Number | |

| A | Pre-filter with 5 micron element | C-FS34 |

| B | Replacement Pre-filter Element | C-F7 |

| C | Coalescing Filter with .01 micron Element | C-CF34 |

| D | Replacement Coalescing Element | C-F7607 |

| E | Tower Replacement ea. (RDD50 2 required) (RDD100 4 required) Change @ 4,000 hrs. | RDDT2 |

| F | Piston Rebuild Kit ea. (RDD50 2 required) (RDD100 4 required) | RDDRKS |

| G | Muffler Assembly (RDD50 2 required) (RDD100 4 required) | RDDM |

| H | Regenerative Desiccant Dryer Timer & Control Block – 115 volt | RDDT115 |