Your cart is currently empty!

Comparing the H1 and H2 Duct Truck – Professional Air Duct Cleaning Equipment

An H1 Duct Truck is built specifically for the heavier chassis- the truck chassis. It’s 6 inches wider than an H2 and it’s built to go on the 1 ton dually such as the GM, the Ford, the Chevy, the Mitsubishi, the Hino, the Cab overs, and it’s basically your big heavy duty set up.…

The First H1 Duct Truck – Professional Air Duct Cleaning Equipment

The first H1 Duct Truck ever made, this was the beginning of the revolutionary new Duct Truck design by Hypervac Technologies that forever changed the way Duct Trucks were made. On this first model of the H1, Hypervac got rid of the PTO drive system, added light weight aluminum construction, created an easy clean out…

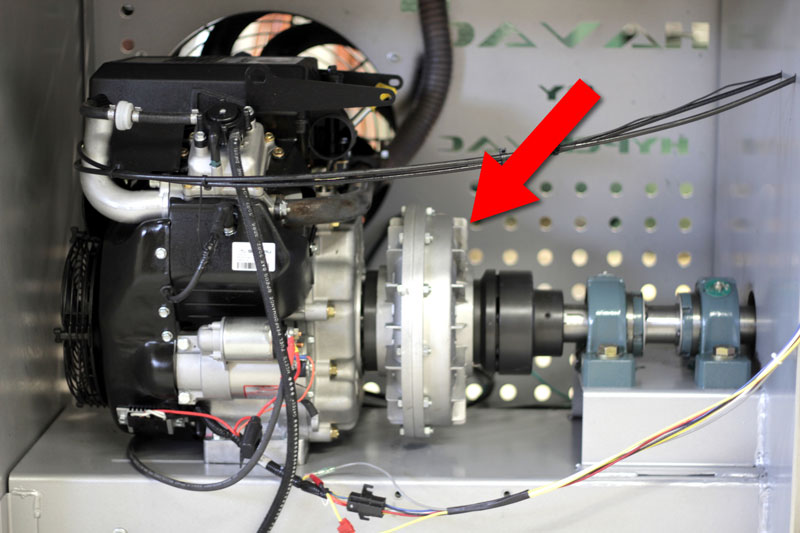

HAVAC Maintenance

Maintenance on the HAVAC is incredibly simple. The HAVAC is the main vacuum used in our H series Duct Trucks, as well as our Cube Vac and H1 Trailer. With any air cooled engine, you have to do maintenance if it’s going to run for many years without a lot of problems. Note that we…

Insulation Removal

One of the big changes we’ve made with our air duct cleaning equipment allows for better insulation removal. It’s so much easier with the H2 Duct Truck or the H1. The hose on the top of the HAVAC vacuum system can easily be disconnected from the top, then turned outwards. With an additional hose attached,…

Duct Truck Bag Doors – No More Getting on the Roof

When we go to conventions and showcase our air duct cleaning equipment, the number one question we get asked is “Why can’t someone create a duct truck that no longer makes you get on the roof to open and close your bag doors?” The H2 Duct Truck design has now solved that problem. No more ladders, no…